This page describes the steps and design parameters for printing textiles at Hackalot using the screen printing method. The screen printing process can be broken down into the following steps and will be explained in more detail below.

Design

Colors

Details

Preparing a screen printing frame

Laser cutting the frame

Tensioning and gluing the mesh

Coating the mesh

Exposing the screen printing frame

Printing on transparency film

Exposing the frame

Cleaning the frame

Transferring the print to textile

Preparing the ink

Squeegee time

Design

We start by designing the file digitally using our favorite image manipulation software. During this design phase it is important to take the rules and limitations of the screen printing process into considerations. Such as not mixing colors and not making the details too small.

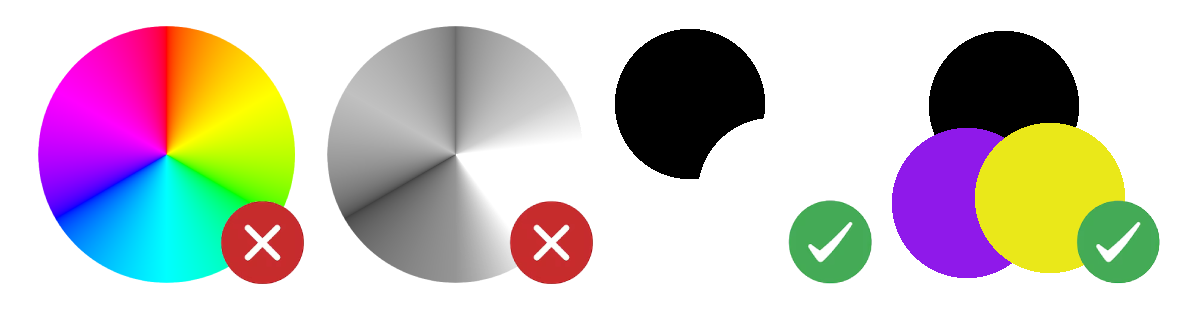

Colors

When designing for screen printing it is important to use a single color or as few colors as possible as you need to make a separate screen for each color you intend to print.

Do not mix colors or shades of gray and use as few colors as possible.

Details

Please take into account that the production of the screen is a photo-chemical process so with increased fine detail requires increased precision / trial and error during the exposing and washing stage.

Try to avoid fine detail such as fine line work, small text and dithering.

Preparing a screen printing frame

To apply the screen printing technique we will need to buy or make a screen printing screen. In the following steps I will explain you how to make one from MDF using a laser cutter.

If you bought a pre-made screen you can skip to the coating step.

Laser cutting the frame

To design a easy to produce frame we have decided to laser cut them out of MDF it is probably better to use a more water resistant material if you plan to reuse the frames often.

Tensioning and gluing the mesh

We used a embroidery frame to tension the nylon mesh before glueing the frame onto it using 2 component epoxy.

Coating the mesh

cleaning & coating

Exposing the screen printing frame

Printing on transparency film

When we have our design ready we have to print it on transparency film this can be done using a regular inkjet or laser printer using the appropriate transparency film depending on printer type. It is important to have a high contrast between the black and transparent areas I have included a few tips to achieve this below.

- Make sure the printer is not in Toner Save Mode or has similar features enabled.

- Use the CMYK color pallet in your image editing software and make sure the K channel is 100%.

- You can attempt printing the same sheet twice.

- Some printers allow you to change the ink amount or density.